In-Mold Decorations in Modern Production: A Comprehensive Overview

In-Mold Decorations in Modern Production: A Comprehensive Overview

Blog Article

Mastering In-Mold Decorations: Strategies, Patterns, and Finest Practices for Optimum Outcomes

In the world of production, the art of in-mold designs stands as a critical facet of product design and production. In-Mold Decorations. By diving into the approaches, fads, and best techniques that underpin successful in-mold decor processes, businesses can open a realm of possibilities that not only elevate the visual allure of their items yet additionally streamline production performance and boost consumer interaction.

Material Option

Product choice is a vital aspect of grasping in-mold decorations, as it straight impacts the top quality and longevity of the final item. When choosing products for in-mold designs, it is important to think about variables such as compatibility with the molding procedure, the wanted aesthetic result, and the ecological problems the item will encounter.

Additionally, materials with high heat resistance are favored for in-mold decors, specifically for products that will be revealed to elevated temperatures throughout their lifecycle. By thoroughly selecting the ideal material for in-mold decorations, manufacturers can enhance the overall quality and durability of their products, satisfying the assumptions of both end-users and customers - In-Mold Decorations.

Layout Innovation

A necessary factor in advancing the field of in-mold decors is the constant exploration and implementation of design advancement techniques. Design innovation plays an important duty in enhancing the visual charm, functionality, and general top quality of items manufactured making use of in-mold decoration processes. By including innovative design components, producers can distinguish their products in the marketplace, attract consumers, and stay ahead of competitors.

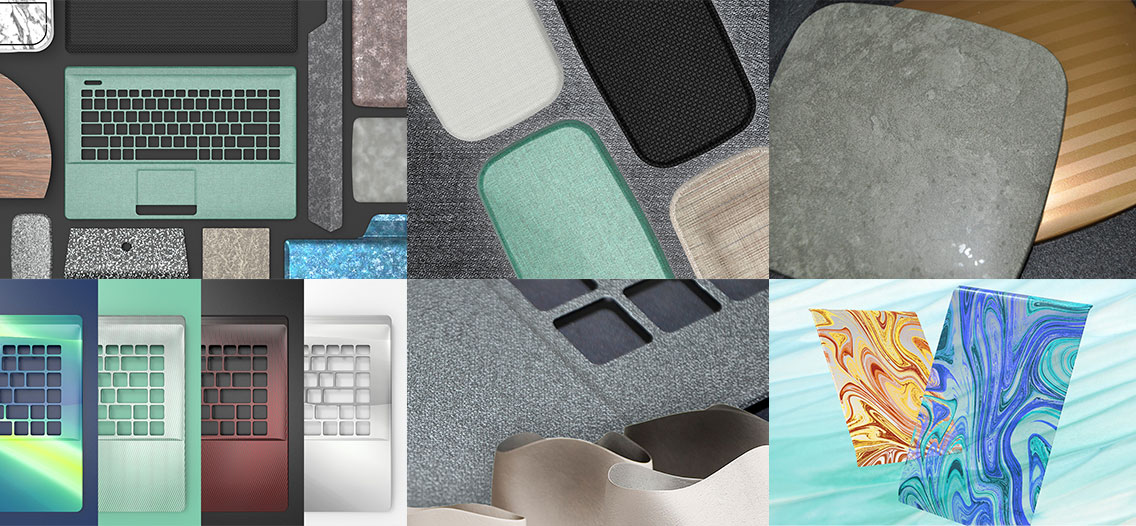

One of the crucial elements of design innovation in in-mold decorations is the integration of elaborate patterns, textures, and graphics that were formerly challenging to achieve with typical decor approaches. Advanced technologies such as 3D printing and electronic layout devices make it possible for designers to create facility and thorough designs that can be perfectly transferred onto molded parts. In addition, making use of vibrant shades, metallic surfaces, and unique effects like gloss or matte structures can even more raise the visual appeal of in-mold enhanced products.

Moreover, layout innovation prolongs beyond aesthetics to include useful enhancements such as ergonomic forms, incorporated attributes, and adjustable aspects that accommodate specific customer requirements. By embracing style technology, makers can open new opportunities for item, imagination, and customization distinction in the competitive landscape of in-mold decors.

Manufacturing Efficiency

Reliable production processes are essential for converting the ingenious layouts created in the field of in-mold designs right into high-quality finished products that satisfy market needs and customer assumptions. In the world of in-mold designs, production effectiveness includes different crucial elements that add to the overall success of the manufacturing process. One crucial aspect is the optimization of mold design and tooling to make sure smooth and specific decor transfer onto the end product. By fine-tuning mold configurations and investing in top quality tooling materials, suppliers can boost performance and consistency in production.

Furthermore, executing automation and robotics in the assembly line can dramatically enhance performance by simplifying repetitive jobs and decreasing the margin of mistake. Automation not only increases the production process but additionally improves accuracy and repeatability, causing a more premium and consistent end product. In addition, embracing lean production principles, such as just-in-time stock monitoring and waste reduction approaches, can even more boost production effectiveness by minimizing downtime and maximizing resource use. Overall, a holistic technique to production efficiency is extremely important in making the most of the possibility of in-mold design techniques and achieving optimum cause the affordable market landscape.

Quality Assurance Actions

What are the crucial techniques for ensuring rigid top quality control actions in the realm of in-mold decors? Quality control actions are vital in in-mold design procedures to ensure the production of flawless and top notch finished products.

Utilizing advanced technologies such as automated evaluation systems can additionally enhance the top quality control process by supplying precise read this article and trusted data for analysis. These systems can find imperfections that might be missed out on by hands-on examinations, thus boosting general item high quality and consistency.

Routine training and development programs for employees associated with the in-mold design process can likewise add to preserving premium standards. By enlightening personnel on best methods, top quality expectations, and the value of interest to information, companies can foster a culture of quality consciousness throughout the company.

Customer Appeal

To improve the bankability of in-mold decoration items, catering and understanding to customer preferences play an important duty in establishing their appeal and success. Customer charm in in-mold decorations is affected by numerous aspects, including style aesthetics, shade choices, longevity, and total performance. Consumers are increasingly seeking personalized and one-of-a-kind items that mirror their originality and style. Therefore, offering customization options such as individualized styles, shade variants, and textural aspects can considerably improve the charm of in-mold decoration items.

Conclusion

In-mold decorations supply a functional and reliable means to boost item aesthetics. Understanding in-mold designs requires an all natural technique that considers all elements of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold designs stands as a pivotal aspect of item layout and manufacturing. Design advancement plays an important function in boosting the visual appeal, capability, and total top quality of items made utilizing in-mold decor processes.One of the crucial read here aspects of layout innovation in in-mold designs is the combination of elaborate patterns, structures, and graphics that were previously testing to accomplish with typical decor techniques.Effective production processes are important for equating the cutting-edge layouts created in the area of in-mold decors right into premium finished products that satisfy market needs and consumer expectations. Providing modification options such as tailored styles, color variants, and textural aspects can dramatically enhance the charm of in-mold decor items.

Report this page